Here's the video link for those who don't like to read:

Introduction:

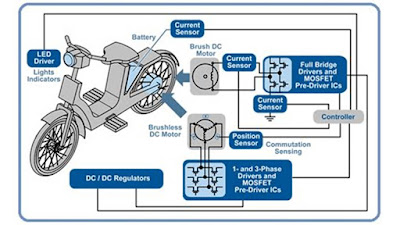

The architecture of an electric vehicle (EV) two-wheeler

system can vary depending on the specific design and manufacturer. However, here’s

a general overview of the key components and their interactions in an EV

two-wheeler system:

§ Battery Pack

§ Electric Motor

§ Motor Controller

§ Vehicle Control Unit (VCU)

§ Battery Management System (BMS)

§ Power Electronics

§ User Controls

§ Instrument Cluster

§ Regenerative Braking System

§ Communication Interfaces

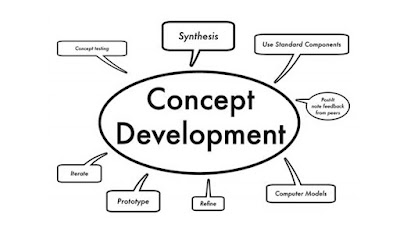

The design and development stages for manufacturing an

electric vehicle (EV) two-wheeler involve several steps that encompass concept

development, engineering, prototyping, testing, and production planning. Here's

a detailed overview of the typical stages involved:

Concept Development:

Identify the target market, customer needs, and market

trends.

Conduct market research and gather insights to determine the

product's features, performance, and price range.

Develop a design concept, considering factors such as

aesthetics, functionality, and market positioning.

Design and Engineering:

Create detailed design specifications based on the concept,

incorporating considerations like aerodynamics, weight distribution, and

structural integrity.

Design the chassis, body, suspension, drivetrain, and other

key components.

Use computer-aided design (CAD) software to generate 3D

models and perform virtual simulations and analysis, including structural,

thermal, and fluid dynamics.

Optimize the design to meet performance, safety, and

regulatory requirements.

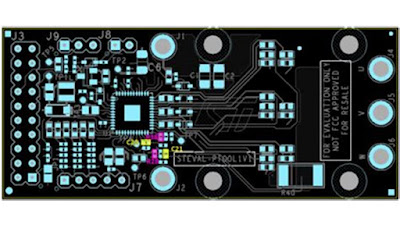

Battery and Powertrain Development:

Design and integrate the battery pack, motor, motor

controller, and power electronics into the vehicle.

Perform system-level simulations and analysis to optimize

powertrain efficiency and thermal management.

Prototype Development:

Source and integrate components from various suppliers.

Conduct extensive testing and validation, including

performance testing, durability testing, and safety testing.

Refine the design and make necessary adjustments based on

the results of prototype testing.

Regulatory Compliance:

Perform necessary tests and obtain certifications from

regulatory bodies.

Address any design modifications or improvements required

for compliance.

Manufacturing Process Planning:

Identify manufacturing equipment and machinery requirements.

Define production line layout and workflow, considering

efficiency, ergonomics, and safety.

Supply Chain Management:

Ensure the availability and quality of components to meet

production demand.

Implement inventory management systems to optimize supply

chain efficiency.

Tooling and Production:

Set up the production line and initiate small-scale

production runs.

Implement quality control processes and inspection

procedures at each production stage.

Monitor and refine the manufacturing processes to improve

efficiency and quality.

Post-Production Testing and Validation:

Perform functional testing, durability testing, and

environmental testing.

Address any issues or defects identified during testing and

make necessary improvements.

Launch and Market Entry:

Establish sales and service networks.

Monitor customer feedback and make continuous improvements

based on user experience.

Conclusion:

It's important to note that the design and development stages may overlap, and iterations and refinements are common throughout the process. Additionally, regulatory compliance requirements may vary depending on the target market and specific regulations governing electric vehicles.